1. PRODUCT DESCRIPTION

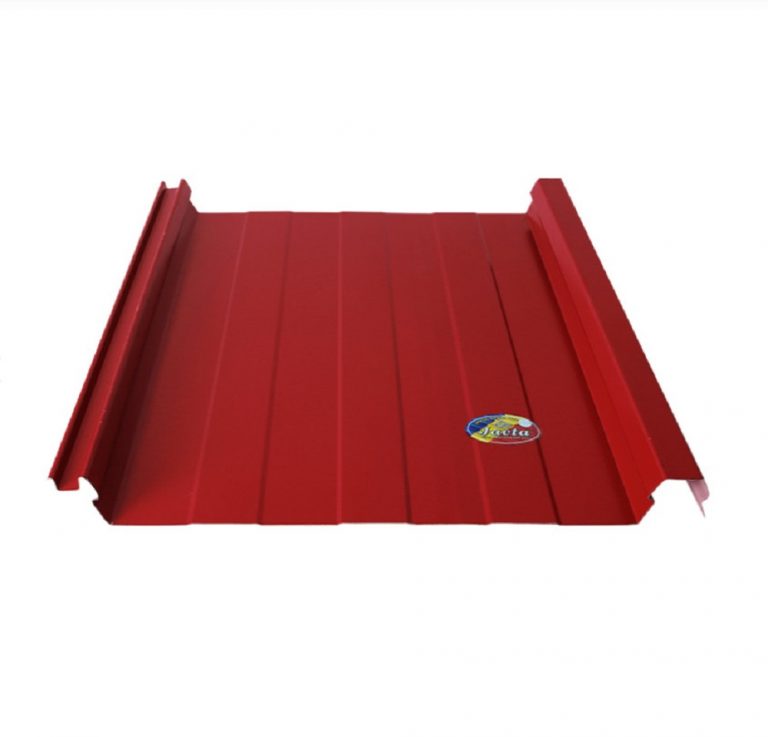

2 waves KLIPLOCK PU JAVTA consists of 3 layers:

First layer: Corrugated iron

Corrugated sheet of KLIPLOCK PU JAVTA anti-leak roof with design of 2 positive waves with a height of 41mm manufactured from galvanized steel products, color coated zinc-aluminum products meeting Japanese industrial standards JIS G3312-G3322; Australian standard AS 2728; European standard EN 10169 with the thickness of the corrugated iron layer can be up to 0.60mm.

Second layer: PU (Polyurethane)

The PU layer is a material with optimal sound and heat insulation, fire resistance, not dispersed in the air and non-toxic to the environment. With a thickness of 20mm PU layer, it can soundproof at 27.5dB and the insulation ability can be different from 4°C to 8°C between the inside and outside environment. To meet all the needs of customers in the application of products that are suitable for use, KLIP PU JAVTA Leakproof Roofing Sheets with sonic PU layer thicknesses are manufactured to order from 10mm – 60mm.

Third layer: PP paper/Alufil paper/Flat corrugated iron

Depending on the needs and purposes of the customer, KLIPLOCK PU leakproof roofing sheet will have the 3rd finish of PP paper/Alufil paper/Flat corrugated iron. Especially with the 3rd layer, which is corrugated iron, we can meet the thickness from 0.30mm up to 0.45mm.

2. HOW TO INSTALL

Kliplock PU wave profile

Assembling 2 heads of Kliplock PU panels

Color coated corrugated iron layer

PU layer 10/25/50mm

Color coated corrugated iron layer/Silver paper/PP

Refer: here

3. SPECIFICATIONS

| KLIP JAVTA LEAK-PROOF ROOFING SHEETS BASIC SPECIFICATIONS SHEET | ||||

| Ordinal number | Classify | Unit | Method | Result |

| 1 | Basic structural components | Corrugated iron+PU+PP/Alufil/Flat corrugated iron | ||

| First layer (Steel) | ||||

| 2 | Corrugated board thickness | mm | 0.35/0.40/0.45/0.50/0.55/0.60 | |

| 3 | Corrugated iron color | According to the company’s color chart | ||

| 4 | Number of waves (positive waves) | wave | JAVTA technical standards | 2 |

| 5 | Positive wave height | mm | JAVTA technical standards | 41±1 |

| 6 | Galvanized background corrugated iron/aluminum zinc | JIS G3312-G3322 standard | ||

| 7 | Coefficient of thermal conductivity | w/m°C | 7194-2000 | 0,028 |

| 8 | Product size | mm | 450mm | |

| 9 | Effective size | mm | 400mm | |

| Second layer (PU) | ||||

| 10 | PU proportion | kg/m³ | Vietnam standard 187-1986 | 35±2 |

| 11 | Moisture absorption rate | % | Vietnam standard 359-70 | 0,38 |

| 12 | Soundproofing ability | dB | Average frequency of the octave band | 27,5 |

| 13 | Load capacity | kg/cm² | JAVTA technical standards | 3,8 |

| 14 | Water absorption rate | % | Vietnam standard 6530 | 0,74 |

| 15 | PU layer thickness | mm | JAVTA technical standards | 10/15/25/40/50/60 |

| Third layer | PP paper/Alufil paper/Flat corrugated iron | |||

4. OUTSTANDING FEATURES OF 2 WAVES KLIPLOCK PU JAVTA

- Absolutely anti-leakage screws

With a special design, the product has a very high positive wave (41mm). Large wave foot helps to increase the stability of the product, especially overcomes the screw foot leak factor and is very resistant to overflow. Reduce noise, withstand large impact force.

The joints of the adjacent corrugated iron sheets are connected vertically at the top to create a water trough for good rainwater drainage, completely eliminates standing water and allows safe use with roofs over 8m long with low roof slope.

- Long life product, great durability

Product size is 450mm, effective size is 400mm with 2 positive waves/sheet. Especially with 3 layers and 2 sides corrugated iron product, we can accommodate the bottom corrugated iron thickness from 0.30mm up to 0.6mm and at the same time, the ability to drain water and prevent overflow is 2 times higher than that of 5-wave industrial corrugated iron, which will help the roof’s life longer.

After screwing, the screws are completely protected in the corrugated iron and will not be oxidized in the environment, increasing the durability of the roof.

- Suitable for many projects with different requirements for insulation and aesthetics

The variety of thicknesses from 0.35mm – 0.6mm helps to completely solve the problem of insulation, increase high fire resistance and aesthetics for the project.

Kliplock Pu Javta 2-wave plate has an anti-opening hem to help increase aesthetics, when viewed from the bottom, it will almost be a ribbed plane. With technical folding, the billet layer of the product avoids direct impacts from the environment.

- Light weight, cost saving

Projects using 2-wave Kliplock Pu products will save costs such as labor and materials, because the roofing sheet is easy to construct and transport, especially it can be manufactured right at the construction site.

When facing problems such as wear and tear, damage to the roofs of large projects, it is necessary to maintain, replace, and dismantle in a large area, for 2-wave Kliplock Pu panels, they will be treated immediately at the area that needs to be replaced.

- Flexibility in transportation and construction

Products with high rigidity are easy to transport, finished roofing thickness and length are flexible depending on the customer’s order, transportation and installation conditions.

- Producing Kliplock PU Javta panels directly at the construction site

With a team of experienced and highly skilled engineers, TYT Vietnam can provide Kliplock Pu 2-wave production machinery system directly at the construction site for production. Kliplock PU Javta corrugated iron production machine at the construction site is not limited in length by transportation factors so it can be produced with lengths up to 80m. Meanwhile, if manufactured at the factory, then moved to the construction site, the maximum length can only be up to 33m. The production at the construction site is an outstanding advantage of TYT, completely overcoming the problems of construction and transportation plans, especially for large projects.

Kliplock Pu production line with 2 flexible waves, automatic control can program many specifications. Besides, the line is designed to be separated into many compact and easy-to-move machine clusters, and easy to assemble at the construction site.

Because of the large roof span, the roof construction minimizes the connection to the roof. Therefore, the leak resistance is superior, minimizing leakage through the roof junction, affecting the quality of the roof construction.

5. APPLICATIONS OF WORKS

- Kliplock PU 2-wave roofing sheet is widely used as a cover for Industrial and Civil projects: factory, warehouse, office, resort, farm…

- The product is installed along the roof length or as an extension.

- Combination of steel frame; U, V, Z accessories.

- Suitable for all constructions, especially works near the sea.

Kliplock Pu 2-wave provided by TYT VIETNAM always meets all the needs of the project from product cost, volume of materials to construction time. Besides, Kliplock Pu 2-wave provided by TYT VIETNAM always bring green space and minimize environmental pollution.

Nearly 20 years of operation in the construction field, TYT Vietnam and Javta factory have been affirming product quality, service in the heart of customers. Thousands of projects and works built with the companion of 2-wave KlipLock PU Javta roofing sheets. TYT Vietnam is proud to contribute to the success of large and small construction across the country such as Sangwoo Garment Project, Long Son Cement Packaging Factory, Bright Vietnam International Factory, Nakano Vinh Phuc Factory,..

The consolidation of construction and customer pleasure is the motivation for us to work harder every day. TYT Vietnam hopes to bring the optimal roof solution for more than works, create a safe living and working environment, more comfortable for the community.

Refer: here